OUR COMMITMENT TO VALORIZE YOUR BUSINESS

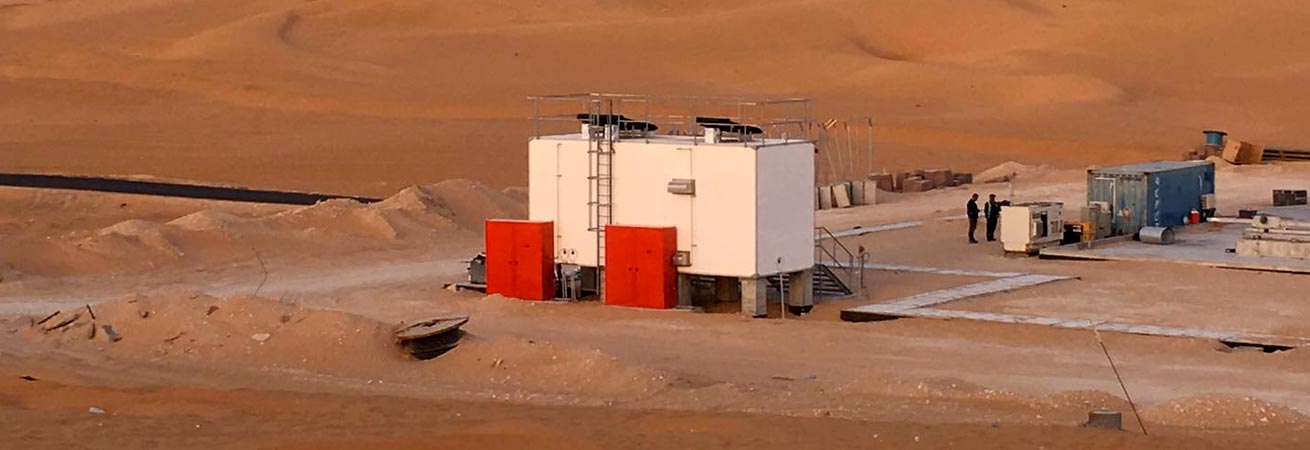

We study, design and manufacture housings and relevant systems and fittings.

The result of our activity has been provided worldwide in various markets

from the Oil & Gas, Telecommunications, Highways and Railways to Defense and Public Administration.